万能卷板机的性能优势知多少?

了解上辊万能卷板机的性能优势吗?什么?不知道?那就好,我这篇文章没有白写,赶紧往下看:

1、高精度的端部预弯

端部预弯时,能够自由地设定直边长度,上辊压下,在一定的压力下,实行高精度的端部预弯。

2、NC控制高的生产效率

一人作业,操作简单,效率大幅度提高。

3、不同的用途相应的控制方法

根据用途,有以下控制方法:TNC(上NC):多品种小量生产用;T&BNC(上下NC):少品种大量生产用;CNC(CNC):多品种大量生产用。

4、制品精度超群

由于连续弯曲,以及高精度的端部预弯,从而得到精度超群的制品;另外上辊呈鼓形状,托辊配合调节,从薄板到厚板这一广泛的范围内能够卷制理想的产品。

5、丰富的弯曲形状

可卷制不同的形状,上辊万能式卷板机的卷曲方式:

O型变曲:后方变曲方式

U型弯曲:前方弯曲方式

特殊变曲:组合式方式

1. High precision end bending

When the end is pre bent, the length of the straight edge can be freely set, the upper end is rolled down, and the high precision end bending is carried out under a certain pressure.

2 、 NC control high production efficiency

The operation of one person is simple and the efficiency is greatly improved.

3, different uses, corresponding control methods

According to the use, there are the following control methods: TNC (NC): many varieties, small amount of production; T&BNC (NC): less varieties, a large number of production; CNC (CNC): many varieties, mass production.

4, precision products superior

Due to the continuous bending, and high accurate end pre bending, resulting in superior precision products; as the top roller is in the shape of drum, roller adjusted, from thin to thick to the wide range of coil ideal products.

5, rich bend shape

It can be rolled with different shapes, and the coiling mode of the upper roll universal plate bending machine:

O variant: rear bend mode

U bend: front bend

Special variant: combination mode

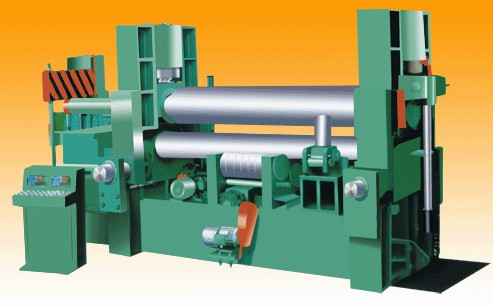

上辊万能式卷板机采用上辊升降液压传动和水平移动(机械传动),由下辊驱动,电气集中控制操作系统,能一次上料完成对板材两端的预弯及卷制筒形、弧形工件的工作,还可以对金属板料进行一定的整形校平,有直接预弯、省事、省料之功效,配置NC系统控制,提高自动化程度。

- 上一篇:四辊卷板机是怎么将工件卷制成型的? 2017/9/22

- 下一篇:选购卷板机的讲究多多,技巧不容小觑 2017/9/20